Thermal blankets can provide your company with a remarkable return-on-investment. Most operations execs understand the benefits of thermal insulation. They prevent heat loss from uninsulated pipes and industrial equipment. Thermal blankets are more or less effective depending on the temperature of the equipment and the room. The effectiveness of thermal blankets also varies based upon their composition. Thermal blankets provide remarkable improvement in insulation efficiency. They also offer a much faster return-on-investment than most other company assets.

To learn more about reusable insulation blankets and how companies use them, read on.

What Is a Removable Thermal Blanket?

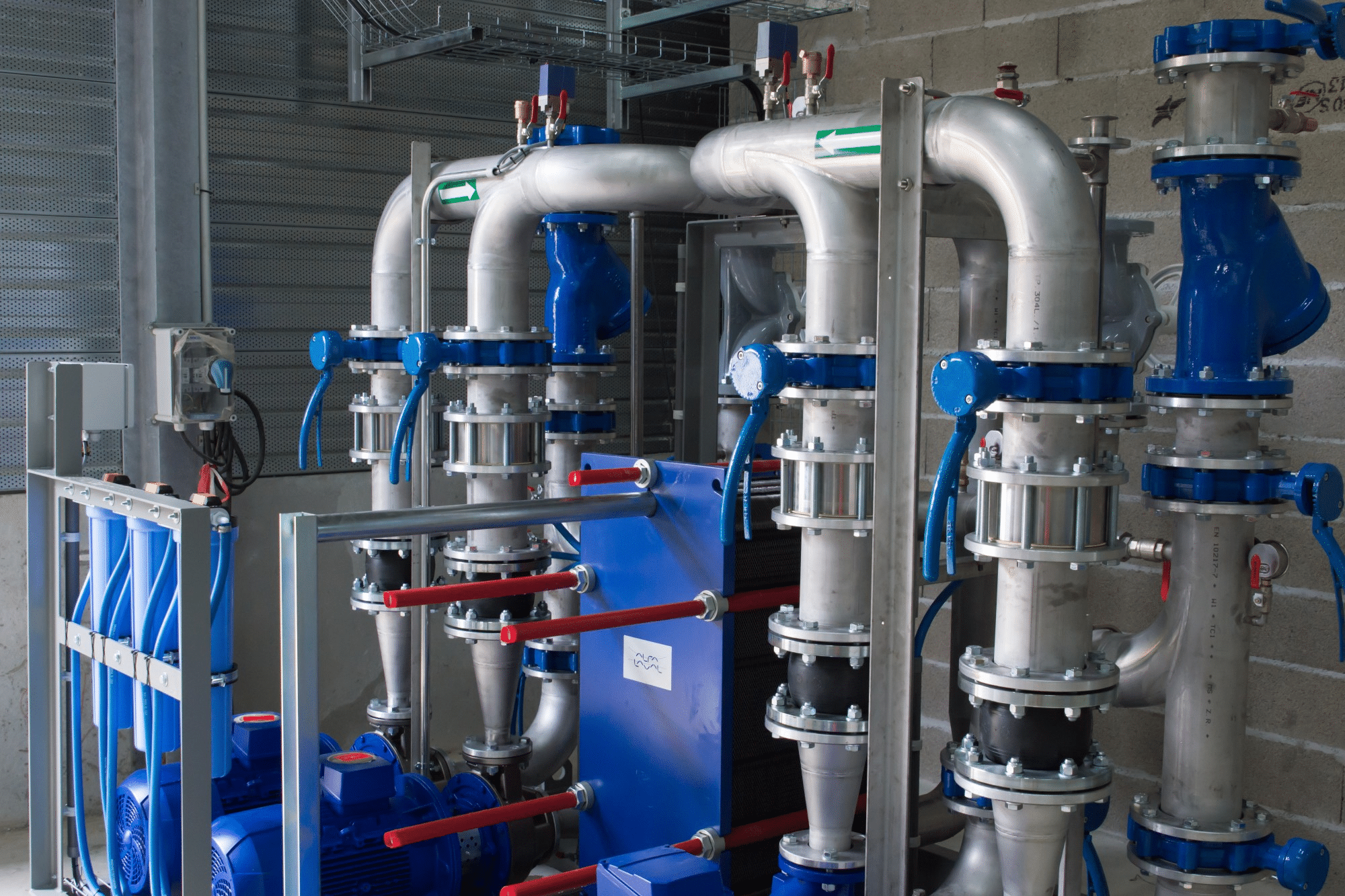

At first glance, a thermal blanket doesn’t seem like that big of a deal. It’s a blanket that goes on the pipe. It has mesh on one side and a cover on the other.

There’s also rivets so that you can attach them to equipment – end of the story, right? Well, there’s much more to thermal blankets.

To begin with, custom insulation blanket manufacturers must create coverings that fit precisely around parts. To accomplish this task, they must also consider any screws, brackets, or other protrusions while designing a blanket. There’s also a matter of choosing the right materials for the application – more on that in a moment.

An industrial thermal insulation blanket is much different from a blanket that you’d use at home to take away a chill in the middle of winter. Highly skilled engineers design them.

Manufacturers make insulation blankets using heavy-duty materials that can withstand extreme elements. An insulation blanket will typically last for years, even under heavy use.

Furthermore, manufacturers can custom fit insulation blankets for nearly any application. No matter what you need, engineers can design a thermal blanket that fits your application perfectly. With the right engineering, manufacturers can create flexible insulation blankets that fit any piece of equipment imaginable.

To find out more about the complexity of creating a thermal blanket prototype, check out this article.

Choosing a Thermal Blanket

There are important things that you should consider when choosing the material for an insulation blanket. The engineers need to know important facts about your application to make sure that they provide you with the right solution.

For example, some thermal blanket materials handle higher temperatures better, while others work well in lower temperatures.

Also, some materials can withstand a wider range of temperatures. This kind of material works well for insulating equipment that experiences temperature extremes that range from cold to hot.

Also, it makes a difference whether you use the blanket indoors or outdoors. For example, some materials are better at blocking UV rays than others.

You must also consider whether the blanket will undergo exposure to substances such as water, oil or chemicals. If you choose the wrong material, abrasive substances can erode the insulation in your blanket.

You must also think about the installation of the blankets. For example, you may need to cover equipment with a unique shape.

Alternatively, you may need to install the thermal blanket in a confined space. In this event, you may want a thinner insulation blanket.

If you use a thermal blanket near heat or fire, you’ll need a material that’s flame retardant. Also, if you use the blanket near water or humidity, you’ll need a blanket that can resist mold.

Insulation Blankets: The Investment That Never Stops Giving

Many facility operators all choose thermal blankets for the same reason – they help companies save money. They’re a better alternative compared to conventional insulation.

Conventional insulation is a permanent installation. That means you can only install it on equipment one time. Removing it involves destroying the covering.

This task takes time. Also, you must buy new insulation to replace the old insulation.

Conventional insulation isn’t effective for covering valves and flanges that require frequent access. For example, you may need to access components for regular maintenance.

A reusable thermal blanket will save your company cost on materials. It will also save the time and effort required for reinstallation.

Despite these benefits, custom thermal blankets still help to reduce heat loss. They help companies save money that they’d otherwise spend on expanded energy.

A removable insulation blanket also helps to support maintenance. Often, factory workers are on a tight schedule.

Many maintenance technicians bypass reinstalling permanent insulation. Most likely, they intend to do it later. However, most often, it doesn’t happen.

Manufacturers do not design conventional insulation for removal. With a custom blanket, however, you can remove it, store it and reinstall it as needed. Over the lifespan of a replaceable thermal blanket, you can save your company hundreds of hours in labor.

Organizations Using Thermal Blankets

Nearly any company can benefit by using replaceable thermal blankets. However, there are a few companies in particular that take advantage of this commodity. For example, you’ll frequently see thermal insulation blankets used in companies that work in industries such as:

Aerospace

Agriculture

Marine

Natural gas

Oil

Power

Many other industries take advantage of replaceable thermal blankets. For example, you may see thermal blankets used at universities, hospitals, and municipal buildings.

Organizations use thermal blankets for everything from increasing energy efficiency to working with hazardous materials. From aiding manufacturing to insulating boilers, replaceable thermal blankets help operation managers run properties more efficiently.

Start Saving Money Today!

Replaceable thermal blankets pay for themselves in a remarkably short amount of time. They help to reduce waste considerably.

Removable energy blankets will help your company to save money on utilities. They’ll also help you to save on maintenance costs.

However, there are added benefits to using removable blankets for insulation. For example, they help to reduce ambient noise.

They also help to reduce air temperature and protect workers from hot equipment. Finally, custom-made removable insulation blankets can give your facility a professional look that’s sure to make a great impression on potential clients.

Leave a Reply