Cutting various types of wire requires the appropriate cutting tool. In any project that involves wires, you’re bound to make measurements and provide the right size for any purpose. But using hand tools can be very dangerous if you’re not careful. Expect tough tools used for cutting to have sharp edges that can injure your fingers. Anyone using wire-cutting tools can benefit from safety precautions that you can find here today.

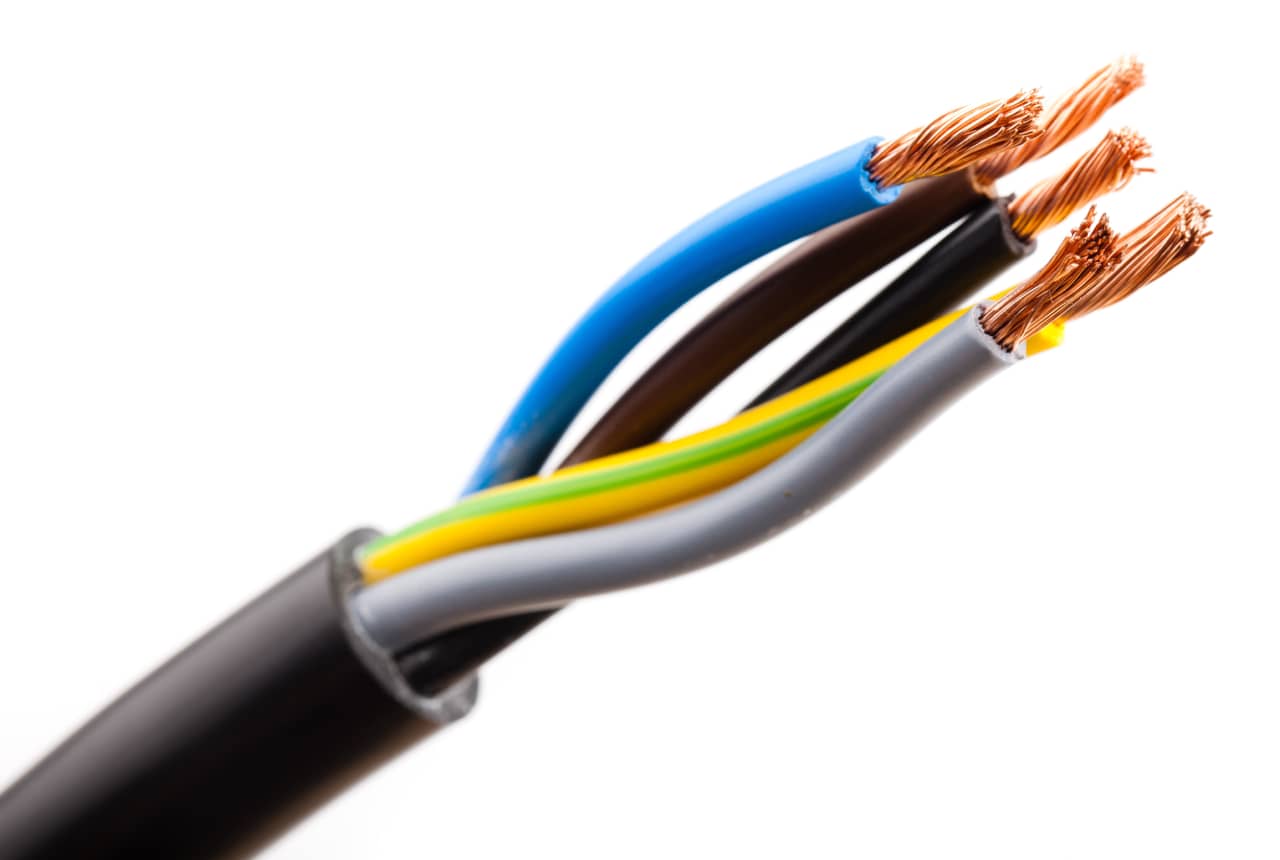

There are two types of wire: hardwire and soft wire. The properties they have will depend on the type of metal they are made of, which is why they vary from soft to hard.

How To Cut Hard Wire

Cutting hard wire isn’t easy with normal pliers, as they can go blunt easily. Maun recommends you choose high-leverage cutting pliers with hardened cutting edges, as these are designed not to go blunt and can cut through even hard wire such as piano or dental wire.

Here are the steps on how to cut wire:

- When using cutters, make sure you’re wearing a face shield, goggles, and protective gloves. If you can find reinforced gloves, the better because some of the ends can be sharp.

- Work on a leveled flat surface, and if you can, work at a height that you’re comfortable with.

- Prepare your wire by measuring it to the length you need and marking it. When cutting multi-strands, use electrical tape to bind the wire and avoid splaying.

- Ensure that the cutting jaws of the tool are aligned to the right angle of the wire length for a clean cut.

- Use force to the grip handles to bring the jaws down and snip the wires. Increase the pressure if necessary.

What Wire Cutters Can You Use?

Wire cutters come in varieties, and some are used mainly for a specific type of wire material. Typically, wires are made using steel and iron, but they can also be made using non-ferrous materials such as aluminum, copper, and brass that are softer and easier to cut. Wires can also be cables that are multi-stranded, electrical, or coax. Rods, fencing, wire ropes, bolts, and concrete wires are also other kinds of wires.

If you’re cutting an electrical wire, you must also use the proper tools for the type of wire you’re cutting:

- Lineman’s Pliers

Use a lineman’s pliers for cutting large wires and cables that are non-metallic. There are also lineman pliers variants that can cut through thinner electrical wires. Moreover, they have multiple uses for stripping and splicing wires easily. Using this often results in a clean and crisp cut. You can use lineman pliers that are perfect for DIY electrical work if you have experience taking on home repairs yourself. - Diagonal Cutters

Small wires can be cut using diagonal cutters. They also come in different sizes and cut wires through indentation and wedging cables apart. Its name comes from how the jaws of the tool can cut at a specific diagonal angle. They are also known as flush cut pliers, diagonal cutting nippers, side cutters, and side cutting pliers. - Needle-nose Pliers

Also known as long-nose pliers, they can get into the deeper parts of multiple wires. A needle-nose plier can twist and snip small wires. They also have various uses, such as gripping and bending. Needle nose pliers provide control and are best suited to cutting projects that require precision, especially when there are parts that are too small to be held by the fingers. - End Nippers

They are also known as end-cutting pliers that can withstand the pressure of cutting stronger and thicker wires. While they are specifically made for cutting electrical wires, they can also be used in cutting a piano wire and other heavier wires cleanly.End-nippers come with longer handles than other pliers, which makes them suitable for cutting through harder material. - Bolt Cutters

Although bolt cutters are designed to cut thick wires such as wire shelving and wire mesh, you may still use them to cut through any type of wiring.As an additional safety precaution, avoid force-cutting steel, iron, and other types of hard wires unless you’re using a specific cutter made for thicker wires. Also, using a hammer or similar objects to pound flat the wire to sever it is not recommended. The composition of the wire is susceptible to breaking, and hazardous debris can scatter from the force.

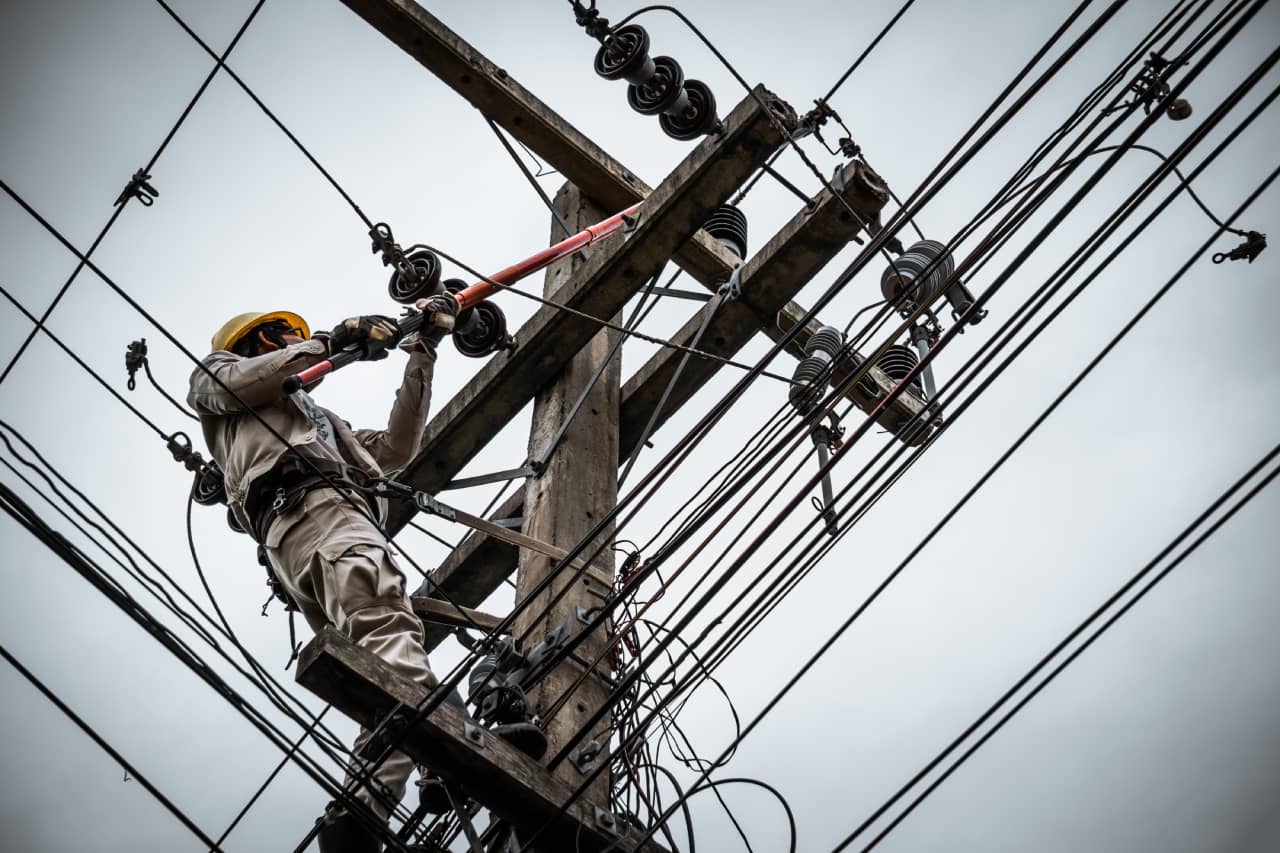

General Safety Tips When Using Cutting Tools

Here are other ways you can minimize the risk when cutting wires:

- Before proceeding to wire cutting, ensure that it’s unplugged if connected to electronics. Find the circuit breaker and make sure that the lever is flipped. Blown circuits, electrical shocks, and devastating fires can result from simply cutting a live wire. Not that the grips on the handle are not made to prevent shocks. Just be sure to buy wire cutters that have insulation.

- There are different cutters designed for various jobs. Use the appropriate pliers for their corresponding wire material, hardness, and size.

- Sometimes, pieces of metal can fly when cut. Avoid injury by wrapping the cutting jaws of the tool with a cloth, burlap bag, or rag. Flying metal pieces occur depending on the material and force used.

- Ensure to cut wire materials across. They must be cut at the edges of the cutting jaws.

- Do the cutting in a clear area where there are no other people who can be injured. If they need to be in the same place where you are, give them a warning at least.

- If the cutter is always used, clean them and apply lubrication regularly. The cutting tools must always be in good condition for efficient cutting.

- Sharpen the jaws of the wire cutting tool according to the instructions of the manufacturer.

In Conclusion

Cutting wire is relatively easy when done with the appropriate material and the cutting tool. It would be best to observe safety measures when cutting wires to avoid injury to yourself and other people in the area. Cutting wires should be done meticulously as it can affect the quality of your work. Doing research and using the right tools saves you time and effort and minimizes risks when doing your job.